Advice for electricians installing with us.

We ask that electricians working with us adhere to these guidelines to ensure a quality installation.

We ask that electricians working with us adhere to these guidelines to ensure a quality installation.

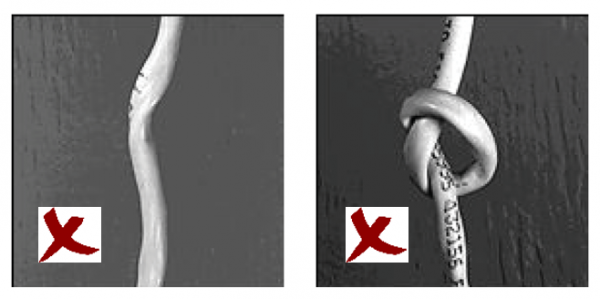

Low voltage cables do not have the strength of main voltage cables so gentle handling is needed.

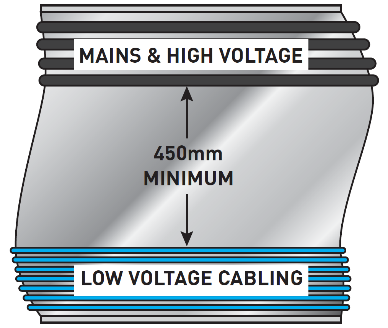

Our low voltage signalling is suceptable to interference so a gap between low and high voltage cables is required.

The quality of the cables makes a difference, we supply the cables to ensure the installation meets the design criteria.

Low Voltage and Extra Low Voltage cabling requires some special consideration when being run around the property. Due to the type of signals they carry, they are susceptible to interference from mains and high voltage cabling.

Avoid running cables parallel to mains/lighting cables.

Cables shouldn’t run parallel to mains/lighting cables for any distance greater than 2m, unless at least 450mm apart.

If cables need to cross mains/lighting cables ensure they cross at 90 degrees.

Do not join cables in any way.

Keep the cable route as short as possible while ensuring some slack at corners.

Don’t allow the cable to form right angles or sharp bends. Use sweeping bends, no tighter than the curve of a Coke Can.

Avoid running cables near electrically ‘noisy’ devices e.g. switching loads such as electric motors, refrigerators and fluorescent lights.

If sockets are not to be terminated, leave tails on all cables as per the cable schedule provided by BrownHen.

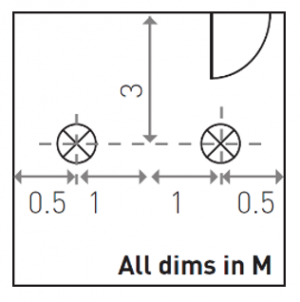

Ensure cable coils (as per cable schedule provided by BrownHen) are left at speaker pre-wire locations to allow for easy installation. Record any pre-wire locations accurately. For example:

Do not create/leave coils of cable part way along a run.

Label cables in a unique fashion using the provided cable schedule as the reference.

Use minimum 35mm deep backbox, ideally 47mm deep backboxes for all sockets; unless specified differently on cable schedule provided by BrownHen.

Ensure cable entry into backboxes is from the bottom of or top of the backbox.

Don’t allow the cable to kink, knot or snag while pulling it off the spool or out of the box; deformation will alter the performance of the cable.

Ensure cables are not unduly hanging under the own weight by supporting the cables at regular intervals.

Do not use undue force when pulling cables; pull cable using less than 25 pounds (11.3 kg) of pull-force.

Ensure all exposed cables (or those run underground) are sufficiently protected.

If cable ties are used, use them loosely. Do not overstress cables by over tightening cable ties, especially to the point where crush-stress is visible.

Below are some links to videos explaining how to wire the lighting head end for Control4 intelligent lighting.

Panellised lighting part I - Covers panels, reports and terminal blocks.

Panellised lighting part II - Wiring terminal blocks. Covers the process of getting the mains voltage wiring in place so that the lighting loads can be turned on.

Panellised lighting part III - Installing the modules. Covers the process of installing the modules and wiring up ready for commissioning.

Panellised lighting - Panel overview - Gives an overview of the panel features.

Contact us for more information